Automatic composite air bubble film machine - Welldoing trading limited

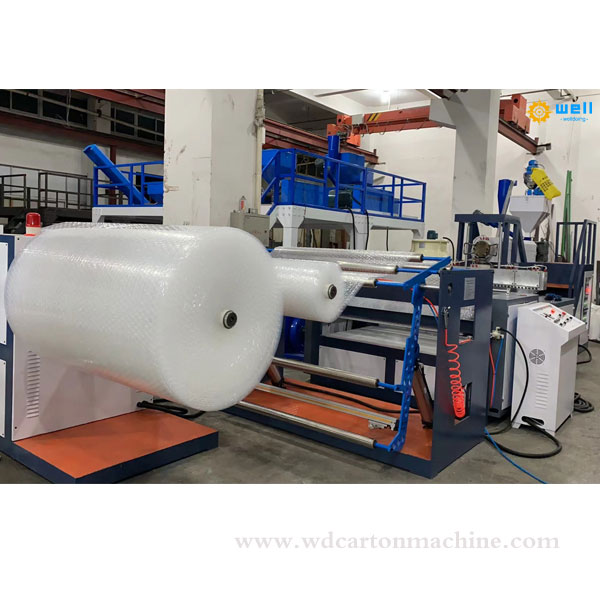

automatic composite air bubble film machine is mainly composed of extruder, die head, vacuum negative pressure system, bubble forming die, traction mechanism, rolling mechanism, winding mechanism, electrical control system and other main components to realize the electromechanical integration product from the addition of raw materials from the feeding port to the automatic control of the winding of finished products.

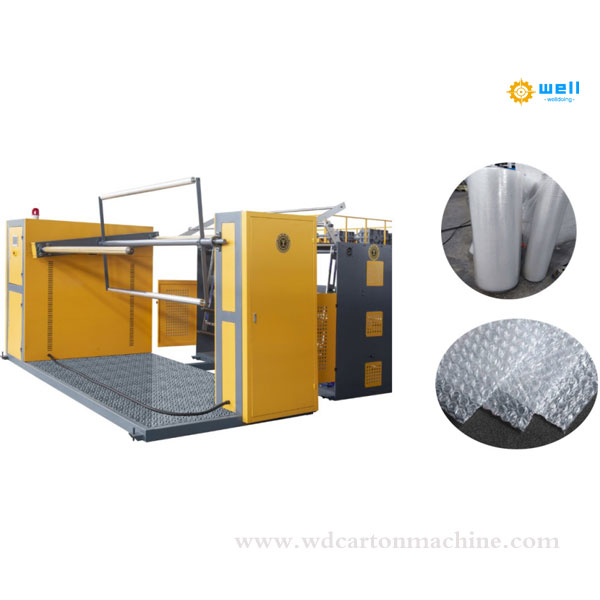

Composite equipment can be customized type: type A: three-layer bubble film. Type B: bubble film of single-sided composite kraft paper, pearl cotton and aluminum foil. Type C: bubble film made of single-sided or double-sided composite aluminum foil or other materials. Type D: five layer bubble film (double layer bubble)

The Air bubble film extrusion line adopts one-time forming process, which is the company’s extensive absorption of advanced technology at home and abroad, and can continuously produce polyethylene composite bubble (PAD) film through a large number of production practice, development and design on the original ordinary equipment. The machine structure design is scientific, practical and reasonable. Composite polyethylene bubble film (PAD) film unit is one of the company’s main products, which has passed CE certification.

automatic air bubble film machine in daily life:

At present, polyethylene is widely used in household air cushion packaging machine, which has the advantages of good anti-corrosion, such as polyethylene air cushion film and polyurethane film. It is also known as polyethylene air cushion packaging machine. It is not only widely used in household air cushion packaging machine, but also has the advantages of good anti-corrosion. Because the middle layer of the air cushion film is filled with air, it is light, transparent and elastic. It has the performance of sound insulation, shock and wear resistance. It is widely used in shock-resistant cushioning packaging of electronics, instruments, ceramics, handicrafts, household appliances, self-propelled cars, kitchens, furniture and paint products, glass products and precision instruments. It can be made into bubble bag, bubble kraft paper envelope bag, automobile sun shield, thermal insulation cushion, thermal insulation material, etc.

By adding different additives to plastic raw materials, various special air cushion films such as anti-static can be manufactured. Anti static air cushion film is used for packaging electronic components and components, such as boards and cards. It can not only prevent static electricity, but also buffer and prevent vibration.

Packaging and Transportation:

Our Services

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling from the very small thing(even a small screw we will choose the best quality) from the beginning

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975