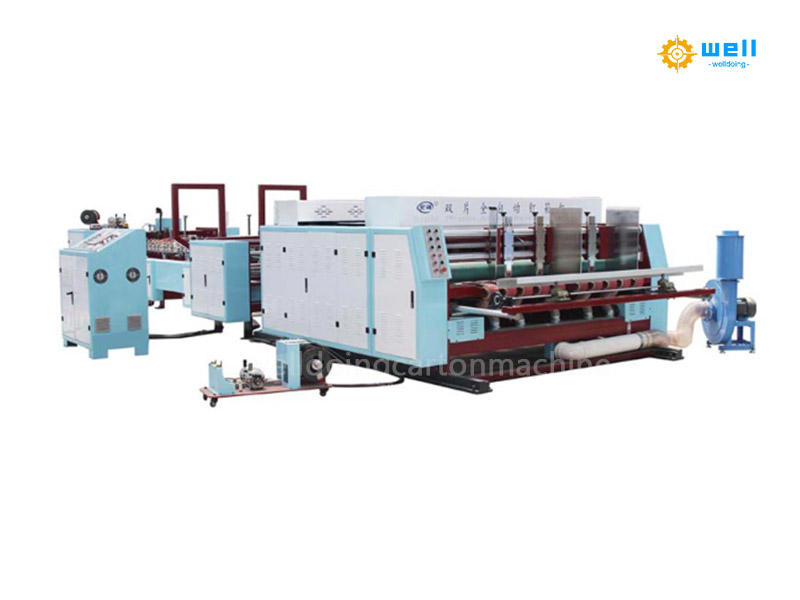

Automatic corrugated cardboard stitching machine - Welldoing trading limited

1.Main parts: (Note: The brand of some parts will change with the machine update, please refer to the machine installation.)

| Number | Name | Brand | Remarks |

| 1 | Send paper servo at the front edge | Yaskawa, Japan | Two sets |

| 2 | Under the nail head servo | Yaskawa, Japan | one set |

| 3 | Lower nail head set feeding servo | Yaskawa, Japan | Two sets |

| 4 | The whole servo | Yaskawa, Japan | one set |

| 5 | Receive paper servo | Yaskawa, Japan | one set |

| 6 | Fender servo | Yaskawa, Japan | one set |

| 7 | On the nail head servo | Yaskawa, Japan | one set |

| 8 | Niling group feeding servo | Yaskawa, Japan | one set |

| 9 | Servo reducer | Li Ming, Taiwan | five sets |

| 10 | frequency transformer | Schneider of France | |

| 11 | Contactor, circuit breaker | Mitsubishi, Japan | |

| 12 | PLC, photoelectric switch, and proximity sensor | OMRON | |

| 13 | auxiliary relay | Schneider of France | |

| 14 | Cylinder, solenoid valve | Yadke, Taiwan | |

| 15 | touch screen | Taiwan Weilun Tong | |

| 16 | razor blade | German alloy tungsten steel production | stand wear and tear |

| 17 | bottom die | German alloy tungsten steel production | stand wear and tear |

2.Function and Features:

1. Automatic box stitching machine adopts servo drives from Japanese brands Yaskawa and Mitsubishi, which are precise and accurate, with fewer mechanical transmission parts, which can effectively reduce the failure rate of the machinery;

2. The contactors in the entire control box are of Japanese Mitsubishi brand;

3. The relay adopts the French Schneider brand, the circuit breaker adopts the Japanese Mitsubishi brand, and the photoelectric and proximity switches adopt the Japanese Omron brand; The cylinder and solenoid valve are from Taiwan’s Yadeke brand;

4. The entire set of nail heads are made of special steel and precision processed by computer numerical control;

5. The bottom mold and blade are made of Japanese tungsten steel (wear-resistant);

6. Can be nailed with a lid box;

7. The power of the nail head is an Yaskawa servo motor, with a mechanical speed of 700-900 nails per minute;

8. Four nails, approximately 50-60 pieces per minute;

9. Automatic corrugated box stitcher machine adopts nine servo drive motor systems;

10. One machine for dual use, capable of nailing single piece to nail cardboard boxes and double piece to nail cardboard boxes;

11. Reinforcing nails can be nailed, with single or double row nails completed in one go;

12. The stacking department automatically counts and outputs, making it convenient for finished products to be delivered and bundled;

13. This machine adopts a computer screen to display fault instructions;

14. Protection device for isolation transformer of the whole electrical equipment;

15. Automatic wire feeding system, no wire alarm, 20KG large flat wire, saving time;

16. Suitable for small and medium-sized cardboard boxes, fast and labor-saving nailing;

17. Suitable for three, five, and seven layers of corrugated cardboard (special instructions are required for seven layers).

detailed description:

The Automatic corrugated box stitcher machine is composed of six parts: the leading edge adsorption paper feeding section, the paper receiving section, the folding section, the stitching box section, the counting output section, and the electrical control section. Adopting Japanese Omron PLC control, touch screen data input, and imported servo motor control for the nail box, the operation is simple and reliable. Automatic paper feeding, automatic folding, automatic correction, automatic nailing, automatic counting, automatic stacking output. Advanced technology and reliable quality.

A. Paper feeding department:

1. The main motor adopts variable frequency speed regulation, with no noise in the system and flexible and stable speed regulation.

2. Adopting a dual servo paper feeding method, the adjustment is stable, efficient, and accurate.

3. The front paper feeding section can be electrically adjusted, suitable for the paper supply needs of various specifications of cardboard boxes, convenient and fast.

4. Equipped with a side tap leveling device to ensure that the paper is not skewed.

B. Primary nailing section: Before the leading edge is fed into the nail box, there is a pre pressing forming wheel to ensure the forming line. It is tapped into position on the front side of the nail box, and the nail mouth is finely adjusted and controllable in size to meet the standard requirements.

C. Paper receiving department: The paper receiving section is a buffering connection that immediately inputs the cardboard nailed out by the head group into the folding section.

D. Folding part

1. Linkage with the paper supply department, variable frequency speed regulation, multiple forming wheels on the upper part to assist in pressing the wire, and the belt is made of imported materials.

2. The imported porous belt is used to transport cardboard, which automatically folds and adsorbs throughout the process, effectively avoiding the phenomenon of skewness, slipping, and stacking of paper in various types of cardboard such as weighted boxes, coated boxes, and polished boxes during work, making the entire machine more stable and efficient.

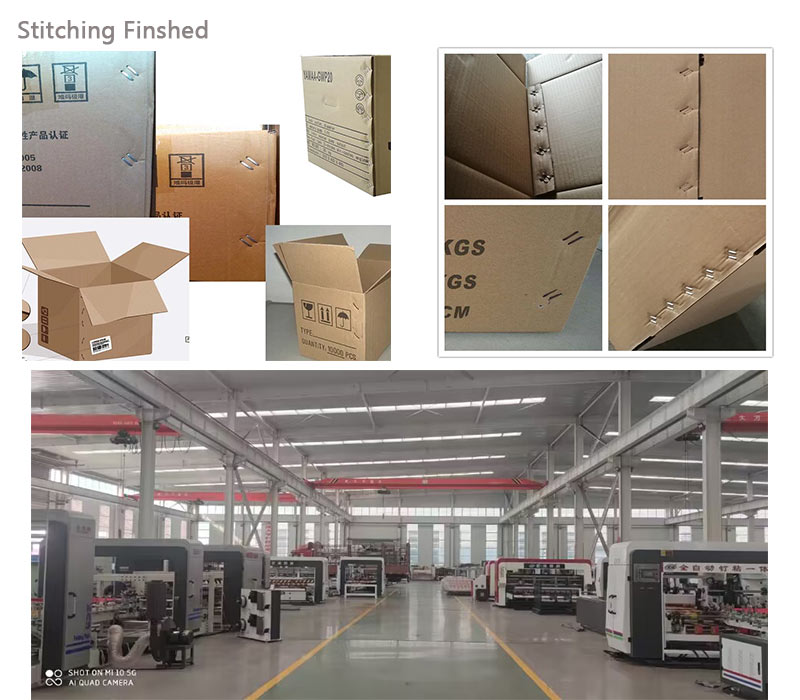

E. Correction department 1. This machine will have a shaping device behind the folding section and before nailing the box. Before nailing the box, the folded cardboard box will be reshaped and leveled again to ensure that there are no scissors on the nailed cardboard box. 2. The calibration department adopts imported servo motor control to improve molding efficiency. F. Nail box part 1. The nail box machine head is made of special material, which is wear-resistant and not easily damaged. 2. This machine features that the nail box head is directly driven by servo motor and Timing belt, with stable and accurate speed and simple mechanical noise free.

3. The nail thread adopts a 4-coil 20kg large flat wire automatic feeding device to reduce the number of wire changes, improve production efficiency, and have a wire absence alarm device.

4. Automatic double piece jiont stitching machine can perform multifunctional operations on cardboard boxes, including single sheet nails, double sheet nails, reinforcing nails, and head and tail nails.

5. The stitching speed can reach 700-900 nails per minute.

G. Counting and stacking output unit After the stitching box department completes the stitching box, the cone code department counts and the stacking department automatically s

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

FAQ