automatic flexo printer slotter die cutter machine - Welldoing trading limited

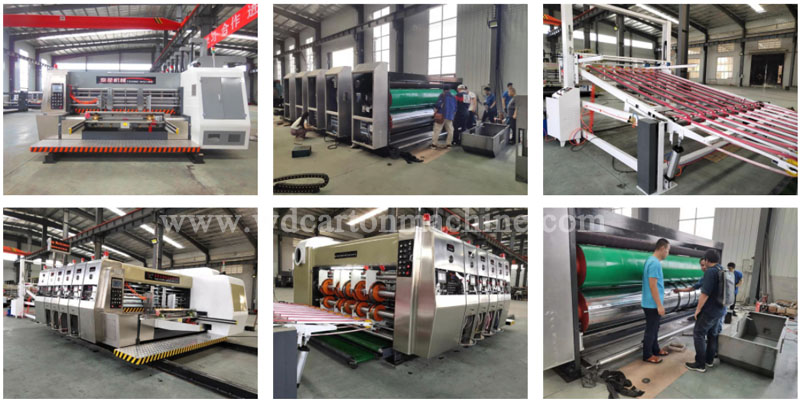

Automatic flexo printing slotting die cutting with stacker machine

Slotted part

High precision imported original linear guide rail, precision helical gear drive, five knife linkage, so that the movement is more flexible and accurate.

*Computer controlled electric adjustment can complete the height, phase and axial movement adjustment of slotted box, which is fast and convenient.

*High quality steel shall be selected for wire pressing axle and slotted axle, which shall be plated with hard chromium after surface grinding; After dynamic balance and static balance correction respectively, the operation is stable.

*The slotting knife is 7mm thick, made of alloy steel, sawtooth heat treatment, tooth grinding, sharp edge and high precision.

*When the slotting box height is adjusted and the upper and lower cutter bases move laterally, an anti-collision protection device is set, which will not damage the machine.

Printing Department

*The printing roller is made of high-quality steel. After static balance, dynamic balance correction and fine grinding are carried out;

*The drum surface is engraved with longitude and latitude lines, which makes the plate loading faster.

*A plate hanging groove is set, and a 10mm plate hanging strip is matched with a ratchet to fix the plate winding shaft, which is convenient for plate hanging. When loading and unloading the printing plate, the foot switch electrically controls the forward and reverse rotation.

*The transverse movement of the printing roller is electrically adjusted, and the adjustment distance is ± 10mm.

*Embossing roller: the surface of the roller body is ground and plated with hard chromium. Dynamic balance correction, smooth operation and manual clearance adjustment.

*Rubber roller inking system: the surface is wrapped with wear-resistant rubber, medium and high special grinding, and the gap is adjusted manually. (optional: sealed knife hanging ink leveling system)

*Anilox roller: with a separate motor-driven idling device to ensure that the ink will not dry up during shutdown. (optional: ceramic anilox roller)

*Printing overprint accuracy ± 0.5mm.

*Automatic cleaning device makes it more convenient and fast to recycle ink or clean.

*Optional: whole process vacuum conveying system.

Paper feeding Department

*The vacuum adsorption roller leading edge paper feeding mode is adopted to realize the characteristics of fast paper feeding speed, high precision, stable system and smooth feeding of curved paperboard.

*Adsorption fan assisted paper feeding, air volume adjustment, suitable for feeding corrugated board of different sizes.

*The left and right baffles are controlled by computer, electric adjustment and digital display.

*The electric adjustment of the rear baffle is intuitive and convenient. The front baffle is adjusted manually, which is simple and fast.

*Double conveying roller structure, the group paper feeding roller adopts floating structure, the gap is manually adjusted, and the adjustment range is 1-12mm.

*The brush at the inlet of the paper feeding roller is used to remove impurities on the surface of the paperboard. A dust suction mechanism is installed between the two groups of paper feeding rollers to suck away the impurities on the surface of the paperboard to improve the printing quality

WELLDOING TRADING Co. Ltd. is a manufacturer + sales and after-sales company, which is mainly engaged in large-scale semi-automatic chain-bar water-based printing machine,automatic flexo ink printer slotter die cutter machine ,High speed ink flexo printer die cutter slotter machine, 2 layers corrugated production line, box-sticking machine, Tying Machine ,automatic partition assembler insert machine, paper core tube making cutting machine, flexo ink printing wastewater treatment machine and so on.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975