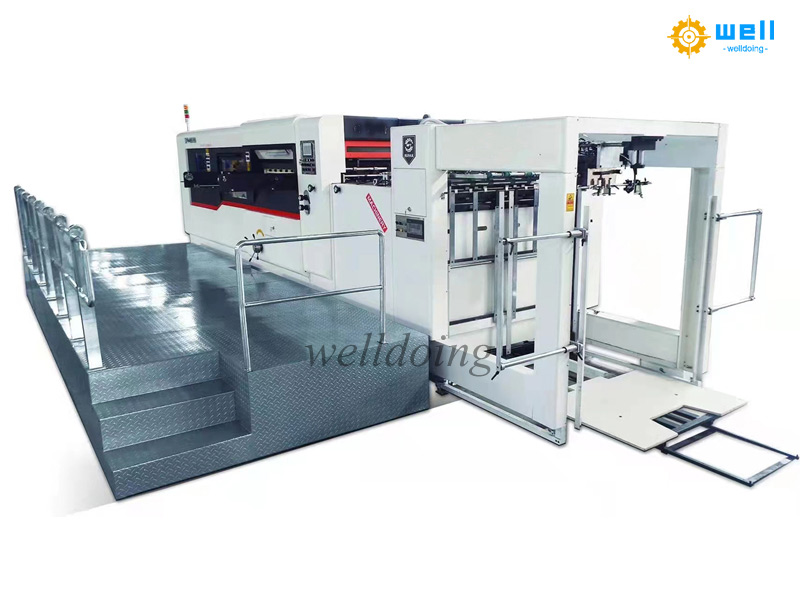

automatic paper feeding die cutting machine with waste cleaning - Welldoing trading limited

Specification Summary:

The automatic paper feeding die cutting machine adopts an independent motion control unit. The power is transmitted by the servo motor and controlled by the control system. It can realize the precise cooperation between the paper feeder and the host, and realize independent movement. The die cutting and stripping machine has automatic movement state, gives full play to the speed advantage of the machine, and is suitable for workers to operate.

Feeding Section:

Be suitable for many different types of paper. The operation space is fully released.

Worm Gear Drive:

Worm gear and worm drive ensures high-speed and stable operation of the machine

Worm gear drive has a good lubrication system

Wall Panel Material: nodular cast iron

Upper and lower platform: nodular cast iron

Five castings: integrated casting

automatic pizza box die cutting and creasing machine

| Type | 1300S | 1480S | 1650S |

| Max. Paper size | 1330×980(mm) | 1480×1080(mm) | 1650×1420(mm) |

| Min. Paper size | 550×480(mm) | 550×480(mm) | 650×550(mm) |

| Max. Cutting size | 1300×960(mm) | 1450×1050(mm) | 1620×1190(mm) |

| Max. Cutting pressure | 250×104N | 300×104N | 300×104N |

| Stock range | Corrugated≤7mmCardboard≥250g | Corrugated≤9mmCardboard≥250g | Corrugated≤9mmCardboard≥250g |

| Cutting precision | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) |

| Max. Mechanical speed | 4200s/h | 4000s/h | 3600s/h |

| Pressure adjusting range | ±1(mm) | ±1(mm) | ±1(mm) |

| Min. Gripper Margin | Gripper ≥8(mm) | Gripper ≥8(mm) | Gripper ≥10(mm) |

| Total Power | 21kw | 25kw | 25kw |

| Machine dimension(include the work platform,pre-feeder) | 7511×4510×2292(mm) | 7708×4650×2292(mm) | 8600×4820×2330(mm) |

| Machine dimension(exclude the work platform,pre-feeder) | 6511×2450×2292(mm) | 6708×2596×2292(mm) | 7600×2805×2330(mm) |

| Gripper/needle numbers/each | 10 | 11 | 12 |

| Total Weight |  ̄18t |  ̄21.5t |  ̄22t |

| Type | 1300QS | 1480QS | 1650QS |

| Max. Paper size | 1330×980(mm) | 1480×1080(mm) | 1650×1420(mm) |

| Min. Paper size | 550×480(mm) | 550×480(mm) | 650×550(mm) |

| Max. Cutting size | 1300×960(mm) | 1450×1050(mm) | 1620×1190(mm) |

| Max. Cutting pressure | 250×104N | 300×104N | 300×104N |

| Stock range | Corrugated≤7mmCardboard≧250g | Corrugated≤9mmCardboard≧250g | Corrugated≤9mmCardboard≧250g |

| Cutting precision | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) |

| Max. Mechanical speed | 4200s/h | 4000s/h | 3600s/h |

| Pressure adjusting range | ±1(mm) | ±1(mm) | ±1(mm) |

| Min. Gripper Margin | gripper≧8(mm) | gripper≧8(mm) | gripper≧10(mm) |

| Total Power | 21.5kw | 25.5kw | 25.5kw |

| Machine dimension(include the work platform,pre-feeder) | 8613×4510×2292(mm) | 8820×4650×2292(mm) | 9180×4820×2330(mm) |

| Machine dimension(exclude the work platform,pre-feeder) | 7513×2450×2292(mm) | 7820×2596×2292(mm) | 8180×2805×2330(mm) |

| Gripper/needle numbers/each | 10 | 11 | 12 |

| Total Weight |  ̄20t |  ̄23.5t |  ̄24t |

Products Advantages:

1.Top quality

2.Large output

3.Delivery timely

4.Competitive price

5.Satisfying service

6.Old and experienced factory

Due to the large size and weight of the equipment, we generally ship by sea. Each machine will be fixed in the container. Also we can wrap it according to customer’s requirement.