Kraft Papaer tube core making machine - Welldoing trading limited

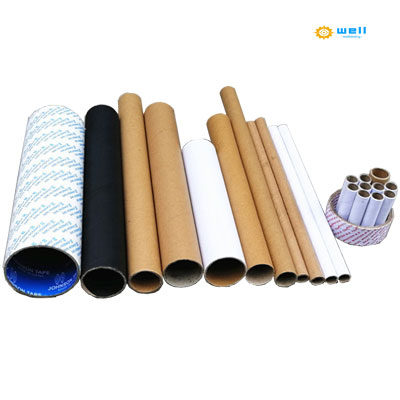

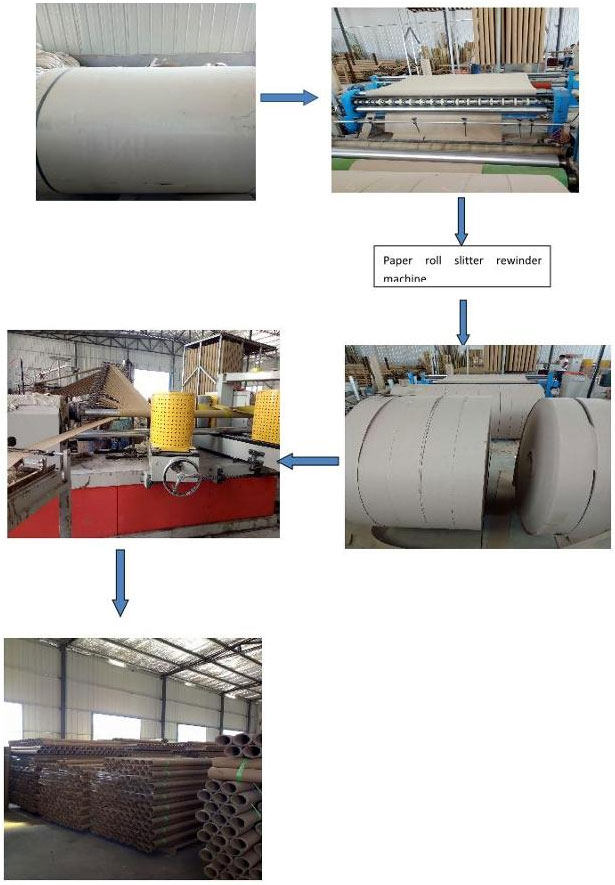

automatic spiral kraft paper core making machine

1. CNC tracking cutting, manually adjust the size according to the order. This structure can make the cutting size more accurate, without secondary fine cutting, thus improving the working efficiency.

2. The main motor is two Shanghai Simic (2.2kW). This product is a gear reducer motor, replacing the traditional cycloid motor, which has the characteristics of low noise, strong power and low failure rate.

3. The cutting table travel is a special product. The motor has the advantages of fast speed, large torque, good stability and accurate synchronization, which can improve the working efficiency and make the cutting length of the paper tube more accurate.

4. The synchronous cutting function of the cutting table avoids the change of the paper gap and the instability of the main machine during the conventional cutting, and improves the quality of the paper tube to the greatest extent.

WELLDOING TRADING Co. Ltd. is a manufacturer + sales and after-sales company, which is mainly engaged in large-scale semi-automatic chain-bar water-based printing machine,automatic flexo printer slotter die cutter stacker machine , high-speed high-definition paper box printing and slotting die-cutting machine, 2 layers corrugated production line, box-sticking machine, Tying Machine ,Automatic Partition Assembler Machine, paper tube making machine, flexo ink printing wastewater treatment machine and so on.

Related products: