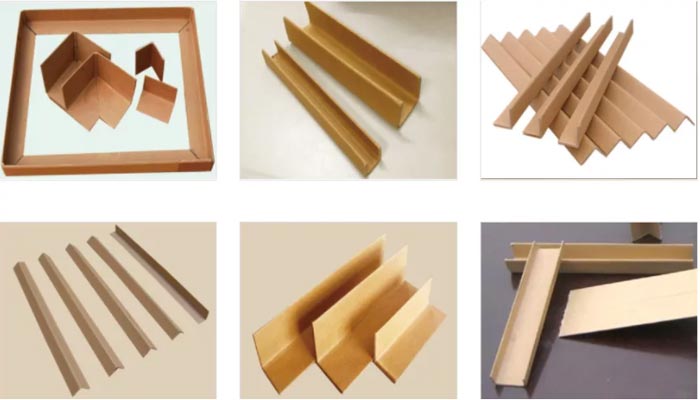

automatic paper edge protector machine china

First, adjust the baffle on the right side of the table top and move the baffle hole to the center of the fixing screw so that the trimming of the plate can be flexibly adjusted during production. Second, according to the size requirements of the work order, adjust the paper knife pressure roller. First, loosen the positioning screw to make the position of the paper separation knife and the pressing roller on the shaft exactly meet the work order size and ingredient requirements, and then tighten the positioning screw.

Adjust the position of the thread pressing wheel and the paper separating knife according to the size required in the work order, and see clearly the requirements in the remarks column when adjusting the thread pressing wheel, whether to use diagonal or concave and convex pressing to ensure accurate pressing.

When tightening the screws of the paper tube Slitter, pay attention to the screws of the upper knife and the lower knife, fix the screws evenly, and do not tighten one screw too tightly. In the production process, the blade will be damaged if the force is uneven.

Adjust the pressing spool so that the distance between the paper knife and the thickness of the paperboard is compatible, so as to ensure that the pressing line is important and not burst, and the edge of the paper separation knife must be clean and free from burrs.

Welldoing is a sales and factory company. We have automatic flexo printing die cutting machine, box gluing machines, automatic partition assembly machinery, automatic paper tube making machine, cardboard production lines, automatic paper edge protector machine. Welcome to consult. We provide good services and free quotations.

Tom (oversea manager) Phone:0086 13303078975 / 17772697357(whatsapp,wechat,line)

Email :cartonmachine.tomwang@aliyun.com

https://www.wdcartonmachine.com

Post time: Sep-06-2022