The operation essentials of the automatic hardboard production line involve multiple links, including equipment inspection, lubrication, adjustment, monitoring, and maintenance. Here are some key operational tips:

• Equipment inspection and preparation: Before starting up, carefully check whether all electrical appliances and steam valves are normal, and ensure that all lubricating parts and chains have been lubricated. For double-sided machines, it is necessary to open all steam valves of the preheater, adjust the upper and lower adhesive discs to the appropriate positions, and ensure that the thin paper is installed correctly.

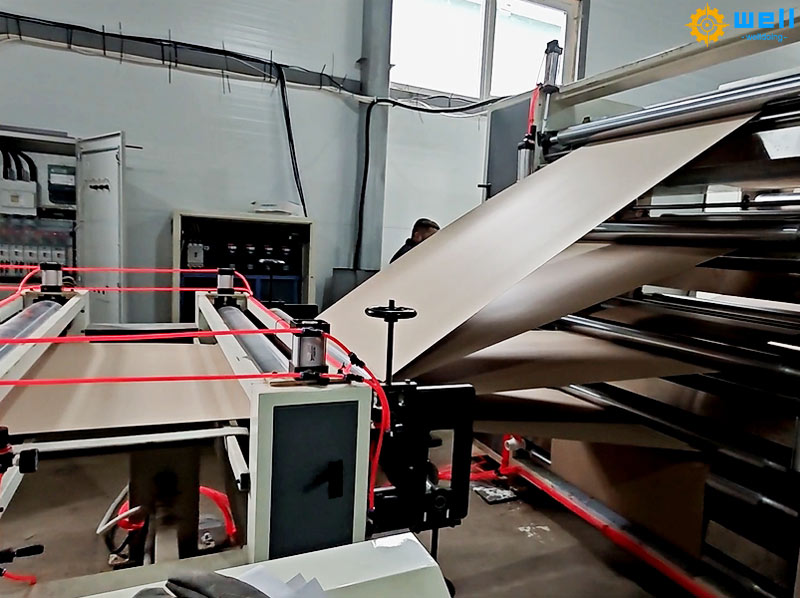

• Coating and drying: During the coating process, it is necessary to observe whether the coating amount is appropriate and adjust it in a timely manner. Ensure that the single-sided cardboard and face paper are aligned and fed into the dryer, and adjust the pressure roller. After production is completed, the equipment should be cleaned and the site should be kept clean.

• Vertical and horizontal cutting: Before starting up the grey board production line , check whether the fastening screws, air pipe circuit, knife and knife groove are normal, and ensure that the paper feeding belt does not deviate. Accurately adjust the cutting width in production to ensure the quality of the cardboard.

• Computer control room operation: The operator should be familiar with the control program, adjust the cutting line and cardboard cutting length according to the production notice and operation manual, and accurately control the quantity of products produced offline.

• Cardboard stacking: Before starting, check if the transmission is off track, lubricate all rotating parts, and ensure that the stacking is neat. Turn off the power after production, clean up the debris on site, and keep a daily production record.

• Safety and maintenance: Operators should strictly follow safety regulations, regularly lubricate and maintain equipment to ensure stable operation of the production line and extend equipment life.

• Quality control: Throughout the entire production process, operators should continuously monitor the quality of the cardboard, adjust equipment parameters in a timely manner, and ensure that the final product meets quality standards.

• Teamwork: The operation of a Paper hardboard production line not only relies on the skills of individual operators, but also requires close collaboration among team members to achieve efficient and high-quality production.

Please note that the above operation tips are based on the information in the search results and combined with the general operation practice of the cardboard production line. In practical operation, the operation manual and safety guidelines provided by the specific equipment manufacturer should be followed.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-28-2024