The working principle of the High speed printer die cutter slotter machine is to first make the words and images to be printed into a printing plate, and then put them on the printing machine. Then, the ink is applied manually or by automatic printer die cutter slotter machine to the places where there are words and images on the printing plate, and then directly or indirectly transferred to the corrugated cardboard or cardboard box, so as to copy the same print as the printing plate.

The roll is small in size and plays a big role. If the rubber roll can not be installed correctly, it will reduce the service life, or it will be scrapped directly. Here is an introduction to the installation and commissioning of the rubber roll. To correctly install the new rubber roll bearing, first clean the impurities at both ends of the new rubber roll, then select the bearing whose specifications and model numbers meet the design requirements, apply lubricating oil on each mating surface, and hammer the bearing sleeve correctly and evenly, Until the bearing is installed in place. It is strictly prohibited to apply force directly on the bearing and knock it at will to avoid damage to the bearing before use. Before installing the rubber roll, the outer surface of the bearings at both ends of the rubber roll and the rubber roll bearing sleeve and bracket on the machine shall be coated with lubricating grease to greatly reduce the rotary impact friction between them due to the back and forth movement of the tandem ink roll, and prevent serious wear on both sides of the rubber roll sleeve and shaft seat.

All kinds of printing and other processing machinery and equipment that practice the production indicators of manufacturers are constantly emerging in the market at the speed of thousands of miles a day, combined with the expectations of manufacturers. However, when these machines are moving towards production goals day and night, many “small problems” related to operation will also occur, such as maintenance.

When automatic flexo ink printer slotter die cutter machine is damaged, the manufacturer generally thinks that it is caused by normal operation wear. However, today’s machinery is made of excellent alloy steel and should be able to be used for a long time. After that, the manufacturers gradually began to find that the material maintenance team played an important role in maintaining the normal operation of automatic flexo printer die cutter slotter machine after constantly paying huge maintenance fees and the painful lessons of delaying production. Among many maintenance materials, lubricating oil and related chemical products were relatively ignored. It may be that the correct selection of these materials will not have an immediate bad impact on the finished products produced by the manufacturer. Mechanical equipment is often used for a long time before it is found to have problems.

A machine for printing words and images. Modern printing presses are generally composed of plate loading, inking, embossing, paper feeding (including folding) and other mechanisms. Its working principle is: first, the words and images to be printed are made into a printing plate and loaded on the printing press, then the ink is manually or by the printing machine applied to the places where there are words and images on the printing plate, and then directly or indirectly transferred to the paper or other substrate (such as textiles, metal plates, plastics, leather, wood, glass and ceramics), so as to duplicate the same print as the printing plate. The invention and development of the printing press plays an important role in the spread of human civilization and culture.

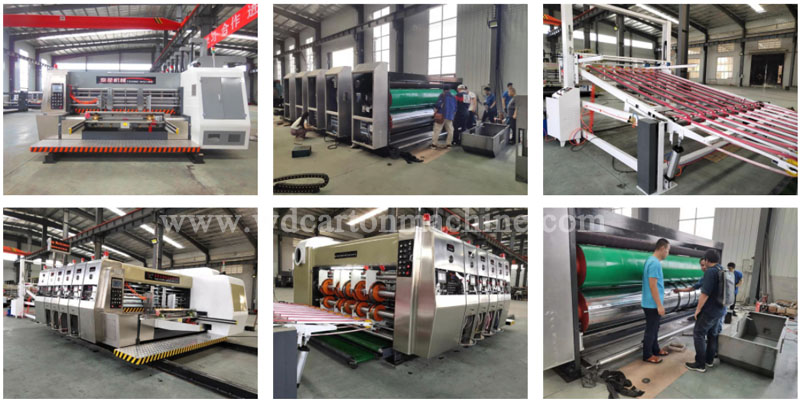

With the growing prosperity of our electronic products, our traditional printing industry has been impacted, and at the same time, it has put forward printing requirements for our printing industry. This has led our printing industry to use equipment with high configuration, and increasingly to use high-speed printing presses. What are the details of the use of High speed printer die cutter slotter machine? Today, I will sort them out for you:

1. Start the engine at low speed and full load, and the acceleration and deceleration machine runs stably with low noise;

2. High speed dot reproduction rate, bright printing effect of layered printing and strong stereoscopic sense;

3. The aluminum guide roller adopts Japanese semi closed bearing and is subject to oxidation treatment. Its appearance is subject to dynamic balance and static balance treatment;

4. Gear rolling is selected, and the printing scale is more. The printing standard is 5mm per tooth;

5. A heating and blowing system is provided. The drying temperature is controlled centrally, and a cooling air shaping device is provided;

6. Stop the printing plate to start and ink, and the printing plate roller will not dry.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jan-03-2023