The failure rate and reliability of Semi-automatic stitching machine is low, and maintenance is crucial. Therefore, the following work should be done well:

1. The upper nail head punch should be lubricated once a day, and the nail head should be disassembled, cleaned, and lubricated every 30 days

2. The lower nail head must be cleaned regularly and the nail head must be disassembled due to the accumulation of small electroplating chips on the nail line falling down and accumulating in the punch

3. Clean and refuel before reinstalling

4. The three gears on the left and right baffles of the paper feeding belt bolt groove shaft should be lubricated with grease every 30 days. The clutch and brake should not have any oil or water entering.

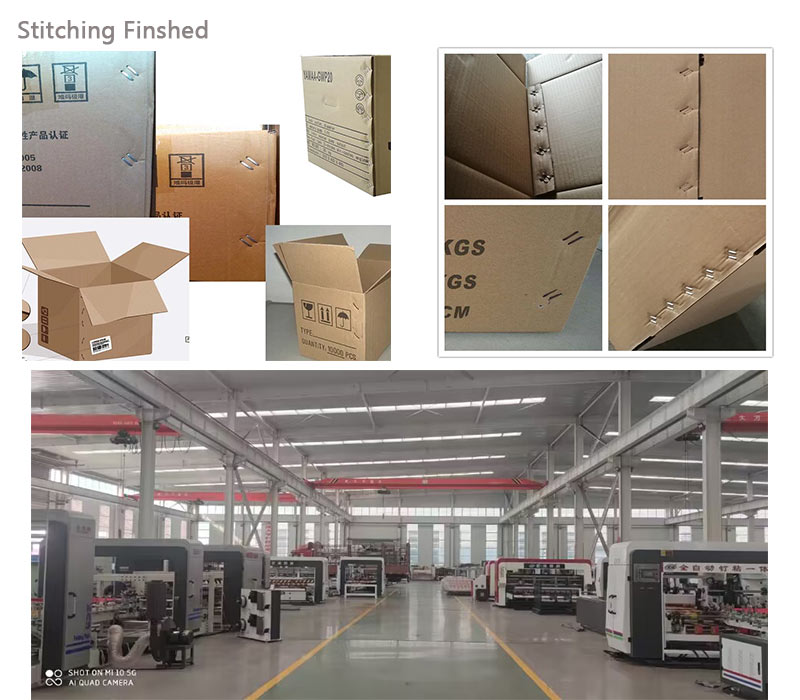

semi automatic carton box stitching machine

5. The servo motor must be kept clean to avoid dust coverage. The heat dissipation and dust filter of the servo motor driver should be cleaned regularly. The electrical control box should be kept clean to avoid short circuits caused by dust coverage. The inner and outer feed line wheel axles should be kept flexible. Use butter to lubricate the nail head fixed shaft and the left and right baffle fixed shaft. When moving, clean and oil lubricate the upper and lower nail head transmission shafts, bolt groove shafts, and transmission screws. Oil lubricate the power transmission box, Apply butter lubrication to gears and chains for 30 days.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jan-18-2024