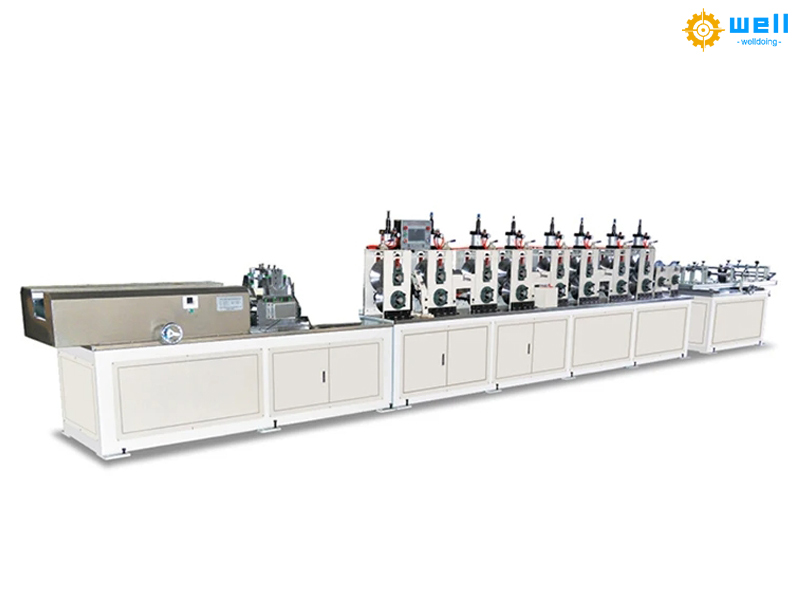

paper angle edge corner protector machine main structure

1. Flanging Part of Paper Feeding

2.Angle protection moulding part

3.Electrical Control Part

4.Cut-off part of guard angle

Maintenance of automatic paper edge protector machine

1. It is very important to check whether the screw of rotating parts is loose and normal before starting the machine.

2. For the lubrication of linear bearings, multi-functional anti-wear bearing lubricants are used. Linear bearings need to be refueled once per shift. If it is more than a week, it should be refueled once before use.

3. Method: Clean the straight-line guide rail, butter nozzle and its surroundings, then press the butter into the nozzle with an oil gun to check whether there is overflow and whether it is evenly dispersed.

4. Clean up the paper dust and dirt in the machine once a day. All electrical cabinets should be closed to prevent dust.

5. The main engine transmission chain should be filled with gear oil once a month. The gearbox should be inspected once a quarter, and gear oil should be added once if necessary. When refueling, the cover of the vent hole should be opened.

6. Check the connection parts and transmission parts of the motor reducer regularly, whether the screw is loose or not, whether it is normal or not, tighten in time to ensure the normal operation of the paper corner protector machine.

7. Attention should be paid to wearing overalls and protective equipment, and gloves.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-13-2024