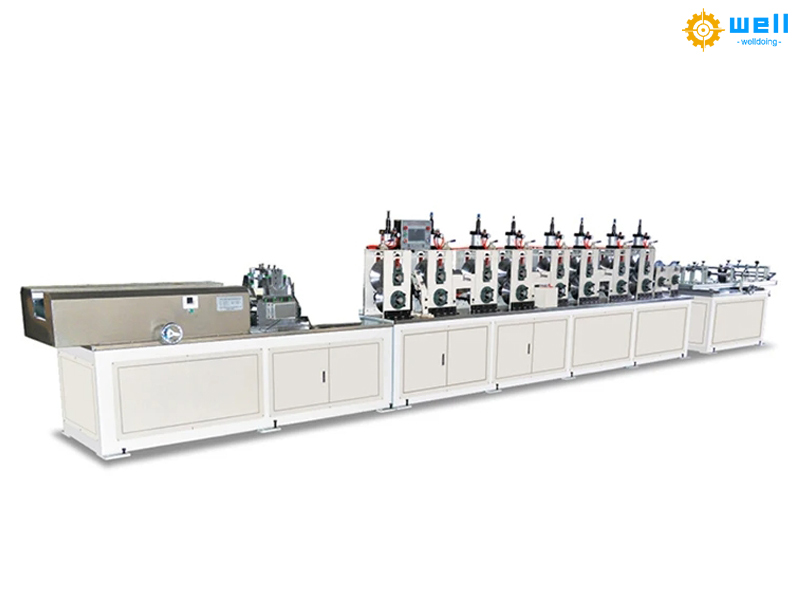

The high-speed automatic paper edge protector machine is mainly used for producing paper corner protectors. The technology of high-speed paper corner protector production lines continues to advance, improving production efficiency and product quality, reducing production costs, making paper corner protectors more competitive in the market, and thus promoting an increase in demand.

production process

Paper feeding: Large rolls of paper are transported to the production line using equipment such as cranes or curved paper feeding racks, reducing labor intensity for workers and improving paper feeding efficiency.

Glue application: Using a two in one glue application system or a combined glue rack, it can achieve single-sided or double-sided glue application, with flexible control of glue amount to ensure even distribution of glue.

Forming: After being coated with glue, the paper enters the forming wheel and is compressed and bent by the forming wheel of the box type suspension structure to form the desired corner guard shape.

Cutting: Advanced technologies such as hydraulic cutting, servo tracking cutting, or flying cutting systems are used to ensure cutting accuracy within ± 1mm and meet different length requirements.

Collection and packaging: The cut paper corner protectors are transported to the collection device through a conveyor belt for sorting and packaging. Manual packaging or automatic stacking function can be selected for automatic packaging.

paper angle board making machine inspection and maintenance

Daily inspection: Operators must inspect the equipment before starting up, during production, and after shutting down. Before starting up, check if all components of the equipment are functioning properly and if there are any signs of looseness or damage; During the production process, pay attention to observing the operation status of the equipment to see if there are any abnormal sounds, vibrations, etc; After shutting down, check if the device is clean and if there are any residual materials.

Regular inspection: Professional maintenance personnel conduct comprehensive inspections of equipment on a regular basis, including mechanical components, electrical systems, hydraulic systems, etc. Inspect mechanical components for wear and deformation, and replace them promptly if there are any issues; Check whether the electrical system is loose or damaged, and whether the electrical components are working properly; Check the hydraulic system for oil leakage, deterioration, and normal pressure.

Equipment cleaning: Keeping paper corner protection production line clean is an important part of maintenance and upkeep. Regularly clean the surface of the equipment of dust, debris, etc. to prevent them from entering the interior of the equipment and affecting its operation. For some difficult to clean parts, specialized tools can be used for cleaning.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Mar-20-2025