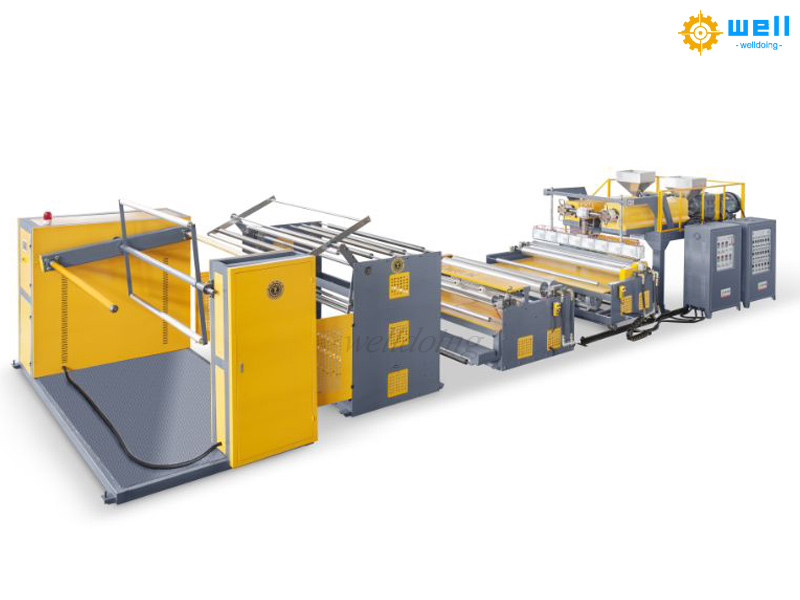

The automatic composite air bubble film machine is made of high-quality polyethylene resin, which is a pressure resistant, moisture-proof, and shockproof packaging filling chemical product. According to the different raw materials, they can be divided into high-quality brand new materials (with bright and white colors) and recycled materials (made from recycled bubble films, etc.), which are dark due to impurities.

What should I do if the automatic air bubble film machine malfunctions? Here are some tips for using a composite bubble film machine.

1. The composite bubble film machine contains impurities. If there is too much dust in the surrounding environment, the machine will break down, and attention should be paid to environmental hygiene. After work, it needs to be checked. If there are too many impurities, corresponding treatment is required;

2. The traction speed of the composite bubble film machine is not constant, but constantly changing, which will affect the operation of the machine. Therefore, it is necessary to check the mechanical transmission to maintain a constant traction speed. Composite bubble film machine products have good shock absorption effect in packaging boxes and a wide range of applications.

3. The Air bubble flim extrusion line series can produce single-layer or double-layer air cushion film machines (air cushion film machines) with raw materials, which are widely used in precision electronic instruments, handicrafts, automobiles, motorcycles, bicycle accessories, etc. This air cushion machine has the advantages of light weight, good elasticity, high transparency, sound insulation and seismic resistance.

Welcome to email for the product detals. We’ll supply the best service for you .

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-22-2023