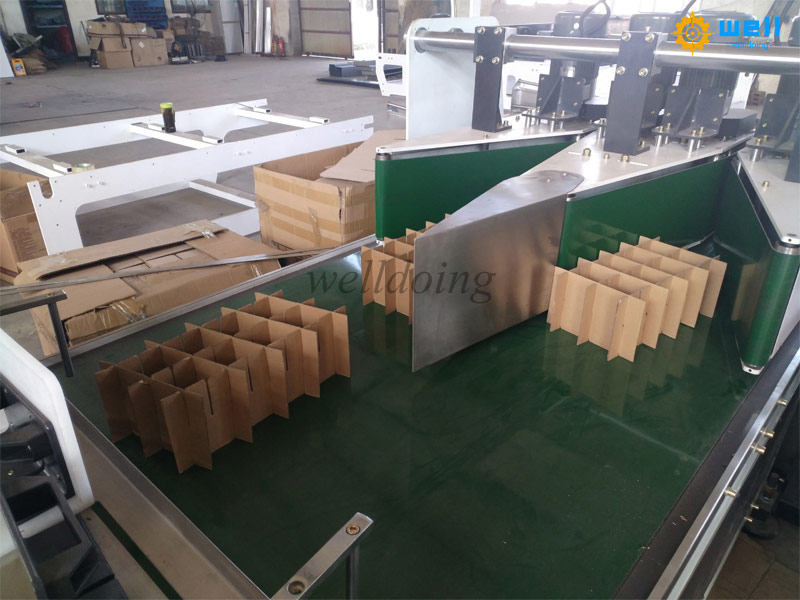

The Automatic partition assembly machine can achieve automatic vertical feeding, horizontal feeding, and automatic slotting by setting up a vertical feeding device, a horizontal feeding device, and a paper opening device, with a high degree of automation and precise slotting. The cardboard longitudinal feeding device of the present invention includes a first conveyor belt and a cardboard longitudinal conveying groove frame. The first conveyor belt passes below the cardboard slotting device, and the cardboard longitudinal conveying trough frame is set above the first conveyor belt. The cardboard longitudinal conveying trough frame is set above the first conveyor belt. There are several longitudinal cardboard slots on the conveyor rack, which are aligned with the length direction of the first conveyor belt. The discharge end of the longitudinal cardboard slot is located below the cardboard slotting device. The longitudinal cardboard can be placed in the first conveyor belt through the groove. Under the conveying effect of the conveyor belt, the longitudinal cardboard reaches the slot position through the slot, and the feeding is very precise. The structure of the longitudinal cardboard feeding device is relatively simple, and a set of conveyor belts can transport multiple longitudinal cardboard.

The cardboard feeding and slotting device of the corrugated carton partition assembly machine places the longitudinal cardboard 100 in the longitudinal cardboard conveying slot 22 through slot 221. Under the action of the first conveyor belt 21, the longitudinal cardboard 100 passes along the longitudinal cardboard. The longitudinal cardboard slot 221 reaches the bottom of the cardboard slot device 4; On the other hand, the horizontal cardboard 200 is placed on the second conveyor belt 31, and under the action of the second conveyor belt 31, the horizontal cardboard 200 reaches the cardboard slotting device 4 below. Then the cylinder 41 of the cardboard slotting device 4 works, driving the slotting plate 42 to lower and continuously pushing the horizontal cardboard 200 towards the longitudinal cardboard 100. After a carton partition assembly machine is completed, the cardboard box slotting board is output in the output direction. The first conveyor belt 21.

The cardboard conveying trough rack 22 of the partition assembly machine includes a support rod 222 and a multi length thin plate 223 installed on the support rod 222. Each group of thin plates consists of two symmetrical long plates 223, with gaps between them. This gap forms a longitudinal paper outlet slot 221, which can pass through a longitudinal cardboard 100. There is also a gap between the lower end of the long sheet 223 and the first conveyor belt 21. When the first conveyor belt 21 is running, the long sheet 223 is in a stationary state. The top of each long sheet 223 is bent outward and opened, making it easy for the longitudinal cardboard 100 to be placed from above into the longitudinal cardboard slot 221. On both sides of the first conveyor belt 21, there are bearing plates 27 for the cardboard guide frame 36 installed on the frame 1, the cardboard guide strip 37 installed on the cardboard guide frame 36, and the length direction of the conveyor belt. The cardboard guide strip 37 is the same as the first conveyor. The length direction of two conveyor belts 31 is the same. The upper side of the second conveyor belt 31 is equipped with a cardboard limit plate 38, and the rear side of the cardboard limit plate 38 is equipped with a cardboard positioning block 39.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-19-2023